Energy Control Procedures shall be used to ensure that the machine or equipment is stopped isolated from all potentially hazardous energy sources and locked out before employees perform any servicing or maintenance where the unexpected energization or start-up of the machine or equipment or release of stored energy could cause injury. 721992 Revision 7 Revision Date.

Infographic Hazardous Energy Control Plan Safetyvantage

Infographic Hazardous Energy Control Plan Safetyvantage

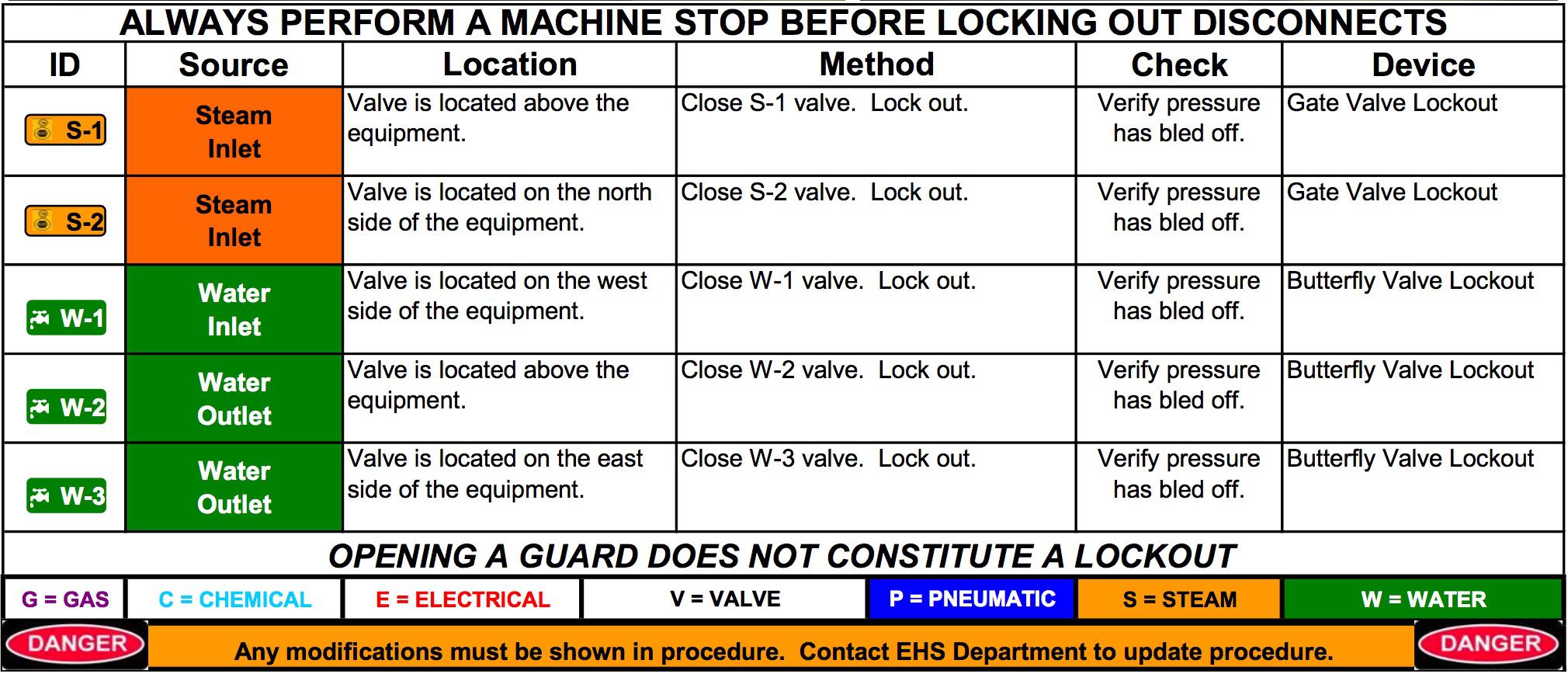

Energy Control Recommended Procedures.

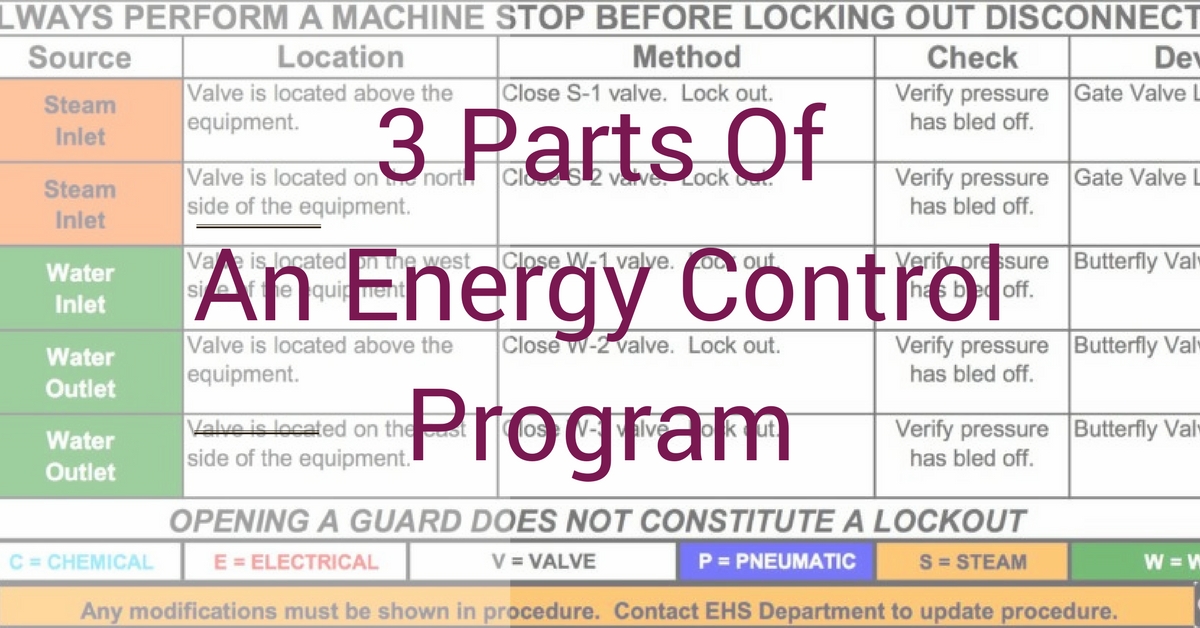

Energy control program. The energy control program has three core components. LOCKOUTTAGOUT ENERGY CONTROL PROGRAM. 2172017 General LOTO Procedure There are six steps for locking out energy and six steps for reenergizing.

The purpose of the OSU energy control program is to clearly define procedures for the control of hazardous energy. Energy Control Program Colby College Page 2 of 12 5500 Mayflower Hill Waterville ME 04901 10 PURPOSE 11 The purpose of this LOTO Program Program is to establish safe work procedures to protect Colby College employees and contractors from injuries related to the unexpected energization start-up or release of stored energy from machinery or. Find out more about our MSc programmes full of academic rigour and entrepreneurial spirit.

The energy control procedure must identify the machine s or equipment on which the procedure is to be used. References 29 CFR 1910147 and 333 NAVMC DIR 51008 Chapter 12. Ad Interested in renewable energy electric mobility or smart cities.

Prepare for shutdown 2. Energy control procedures employee training and periodic inspections. Hazardous energy control is a broad term describing the use of procedures techniques designs and methods to protect personnel from injury due to the inadvertent release of hazardous energy.

It is a very important part of machine maintenance and production servicing operations. In America it is a requirement from OSHA to have this type of program in place but more importantly it is a proven way to minimize the risk of injuries and even fatalities for those who work with dangerous equipment. A comprehensive written diligently planned and executed Hazardous Energy Control Lockout Program protects the life and the safety and health of workers.

A lockout tagout program is an effective way to control hazardous energy in virtually every environment. The purpose of the Energy Control Program ECP is to provide written policies and rules within your safety management system that help prevent accidents like this. These procedures cover the servicing and maintenance of equipment in which the unexpected energizing start up or release of stored energy could cause serious injury to employees.

Energy control procedures detail and document the specific information that an authorized employee must know to accomplish lockouttagout namely the scope purpose authorization rules and techniques to be utilized for the control of hazardous energy. Hazardous Energy Control - LockoutTagout. Find out more about our MSc programmes full of academic rigour and entrepreneurial spirit.

This program applies to the control of energy during servicing andor normal. Companies must have a program outlining the steps to de-energize machines and lock out sources of energy. The program will work best when it is recorded in a Written Procedure.

In these links 1-5 we offer sample written programs with different complexity levels. Develop an Energy Control Program ECP What management action should occur to help prevent fatalities or injuries due to the unexpected startup of equipment or the release of stored energy. An employee is required to place any part of his or her body into an area on.

No worker should die or be injured due to the unexpected startup of machines and equipment or release of stored energy. Hazardous Energy Control Lockout and Other Means Resource Guide. Hazardous Energy Control LockoutTagout Program Template.

Energy Control Program by MCIEAST. LockoutTagout Energy Control Program Environmental Health Safety Shop Safety Procedure Page 3 of 8 Origin Date. A machine or piece of equipment where work is being performed at or upon.

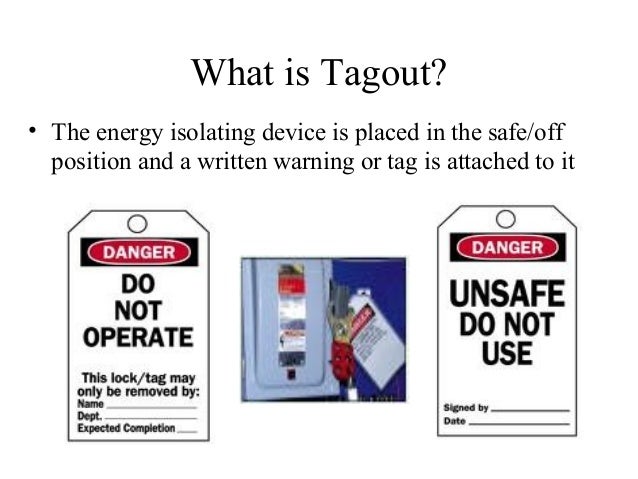

Maintenance of machines and equipment if. Lockout is the placement of a lock or tag on an energy-isolating. Purpose Lockouttagout procedures are designed to prevent needless deaths and serious injuries to service and maintenance personnel by controlling hazardous energy.

Ad Interested in renewable energy electric mobility or smart cities. The energy control procedures must identify the type and magnitude of the hazardous energy and the means and methods that will be used to protect employees during servicing or maintenance operations. An employee is required to remove or bypass a guard or other safety device.

Energy Control Procedure The Catalyst Group

Energy Control Procedure The Catalyst Group

3 Parts Of An Energy Control Program The Catalyst Group

3 Parts Of An Energy Control Program The Catalyst Group

How To Improve Lockout Tagout Loto Safety Safesite

How To Improve Lockout Tagout Loto Safety Safesite

Lock Out Tag Out Energy Control Program Safety Resources Indianapolis

Osha S Top 10 Energy Control Program

Osha S Top 10 Energy Control Program

Lock Out Tag Out Energy Control Program Safety Resources Indianapolis

Lock Out Tag Out Energy Control Program Safety Resources Indianapolis

Energy Control Lockout Tagout Ppt Download

Energy Control Lockout Tagout Ppt Download

Control Of Hazardous Energy Lockouttagout Osha 29 Cfr

Control Of Hazardous Energy Lockouttagout Osha 29 Cfr

Energy Control Program Lockout Tagout

Energy Control Program Lockout Tagout

Energy Control Lockout Tagout Program Online Training

Energy Control Lockout Tagout Program Online Training

Lockout Energy Control And You Learning Designs Inc

Lockout Energy Control And You Learning Designs Inc

3 Required Parts Of An Energy Control Program Convergence Training

3 Required Parts Of An Energy Control Program Convergence Training

Osha S Top 10 Energy Control Program

Osha S Top 10 Energy Control Program

Energy Control Program By Mcieast

Energy Control Program By Mcieast

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.